What is biodegradable packaging?

Biodegradable packaging is generally defined as any form of packaging that will naturally disintegrate and decompose.

Biodegradable Definition:

The term “biodegradable” has typically been used very broadly for any sustainable packaging material that will naturally break down – under any conditions and in an undefined amount of time. The issue? By this definition, anything from a wooden box to a cellulose-based wrapper is biodegradable. The difference being that the wrapper will biodegrade within weeks, while the wood will take decades or even centuries. Some of the sustainably-stamped biodegradable packaging that is being sold today will still cause harm to the environment!

So, how can you find a biodegradable package that will break down in a safe environment in a reasonable amount of time?

How to Identify if a Package is Biodegradable

What are biodegradable materials for packaging?

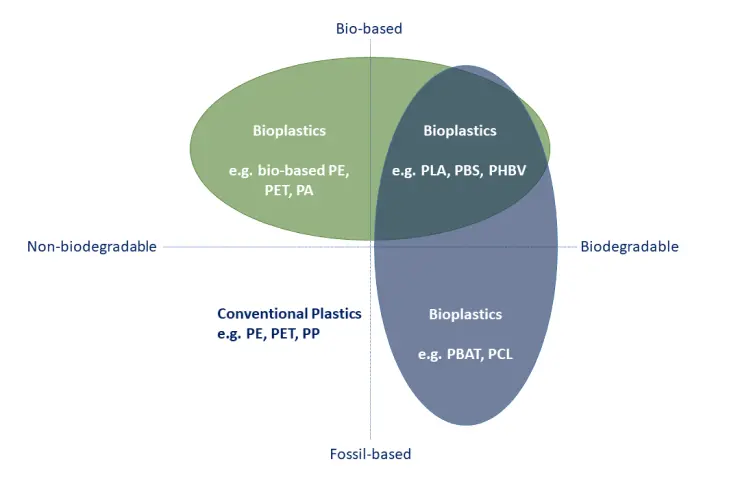

What’s the difference between non-biodegradable and biodegradable plastics if they can both be made from fossil-based polymers? Conventional plastic packaging is made up of strong carbon chains (like PE, PET, and PP) and takes a long time (centuries!) to break down, so these are not considered biodegradable.

Biodegradable packaging, such as paper or cellulose, has a weak molecular structure so it will disintegrate quickly.

What is a Fossil-Based Polymer?

A fossil fuel is a hydrocarbon-containing material formed underground from the remains of dead plants and animals that humans extract and burn to release energy for use (like gasoline or natural gas). Fossil fuel, just like other organic materials, is made up of carbon chains.

Fossil-fuels are usually identified with the strongest, non-biodegradable plastics. However, there are some petroleum-based plastics composed of weaker types of carbon chains, which degrade efficiently and completely (like PBAT) while maintaining the strength and flexibility that makes plastic packaging so attractive for packaging manufacturers and users. These are ideal for biodegradable food packaging, as they provide the durability and reliability of plastic, with the environmental benefits of biodegradability.

TIPA, one of the world-leaders in specialized R&D for compostable packaging, uses a blend of fossil fuel-based and bio-based materials in our certified biodegradable films and packaging.

What are the types of biodegradable packaging?

- Hemp: Sourced from the cannabis plant, hemp is highly biodegradable, resilient, and versatile. However, hemp is still an expensive source for bioplastics and not yet commercially available in its polymerized form.

- Paper: Paper is one of the oldest, traditional forms of compostable packaging. It biodegrades very rapidly and can easily and efficiently be recycled. The downside is that paper does not provide the same protection or sealing as other kinds of packaging, so it’s not appropriate for a lot of food packaging.

- PLA: PLA is bio-based and can be molded like conventional plastic into packaging, however it’s slow-composting, even in an industrial composter.

- Cellulose: Plant-based packaging degrades very easily and is a great solution for short-term packaging, but it can’t provide shelf-life or proper barrier for food products and easily discolors when stores.

- Seaweed: Like cellulose, seaweed-based material is highly biodegradable, and a great for short-term packaging, but unstable and unsuitable for food packaging, transport and storage.

Biodegradable food packaging demands a hardy, protective material that will protect the product’s freshness and integrity, while being able to withstand the necessary transport and storage conditions over many months. At the same time, it must be fully biodegradable within a reasonable amount of time.

TIPA compostable packaging is partially bio-based and partially fuel-based with specialized polymers that are highly durable yet easily biodegrade at end-of-life.

Why is it important to have biodegradable packaging in our world?

Waste, in all its forms, is one of the most pressing environmental issues of our time. Every year, some 8 million tons of plastic ends up in the ocean.

As the world’s population explodes, and consumerism drives more manufacturing and distribution of products, the amount of waste in oceans and landfills worldwide continues to rise.

What is the end game? How can we begin to walk back our impact on the planet?

There is no one solution to the eco-crisis. It demands a multi-pronged approach, and biodegradable packaging is one essential tactic among several that will save our planet.

The global supply chain is complex – there is no easy return to the culture of local manufacturing. There is an urgent need for a healthier, smarter, and natural packaging solution that can accommodate contemporary consumer needs while keeping our planet safe. That solution is biodegradable packaging.

Is biodegradable packaging good for the food industry?

There’s a big difference between throwing away a banana peel and a plastic bag. They might both be used to package food, but the banana peel is biodegradable and will disintegrate naturally while the plastic bag will last for decades if not hundreds of years, lingering in a landfill, leeching harmful chemicals or possibly polluting the oceans.

Food is purely organic waste, the ultimate compostable material. But much of the packaging of food products is not. It’s shocking to consider that 63% of solid waste produced in the US comes solely from packaging. And this figure continues to rise.

By switching to biodegradable plastic packaging, the food industry can leverage this massive source of waste and re-direct it to compost, cultivating nutrient rich soil to support farming to grow more food. Instead of damaging the environment, biodegradable food packaging can become part of a vital circular system that both eliminates waste and boosts food production.

This critical advantage makes compostable packaging the next generation packaging solution for the food industry. New technology makes it possible to produce biodegradable food packaging that is also durable. So, more of our waste can ‘behave’ like a banana peel, rather than a plastic bag.

What are the Benefits of Biodegradable Packaging?

The advantages of biodegradable plastic packaging are clear for the environment, for the future of the planet, and for the sustainability of the food industry at scale:

Supports farming

Biodegradable food packaging drives the circular economy, leveraging packaging waste as compost that adds nutrients to the soil and helps boost food production and farming.

Healthier solution

Biodegradable food packaging is nontoxic and natural, providing a safe and healthy solution for all types of food and food products.

Reduces Waste

The most important benefit of biodegradable packaging is the potential to reduce overall waste in the food industry. Instead of discarding tons of plastic to languish in landfills for decades, biodegradable food packaging naturally and completely degrades.

Returns to nature within a set time

Certified compostable packaging, such as TIPA, is designed to biodegrade under regulated conditions within a standard time-period. Packaging that is certified as biodegradable will break down typically within a year in home compost bins, and within 3 to 6 months in industrial composting environments.

Global food brands turn to TIPA for smart biodegradable packaging

Natoora

Organic fruit and vegetable delivery

Grupo Bimbo

World’s biggest baker commits to 100% sustainable packaging

Aquibio

France’s first organic frozen produce supplier

Explore TIPA's catalog

TIPA biodegradable food packaging solutions are not just great for the environment, they are also durable and hardy for proper transport

and storage of sensitive food products according to health and safety regulations. Their films run on conventional plastics converting and packaging machinery and fit in easily with the plastic packaging supply chain.

The TIPA solution is easily integrated into existing packaging machines and systems, making it a cost-effective and viable alternative to current packaging operations.

Explore TIPA’s range of biodegradable and compostable films and laminates, pre-made packaging, and printed reels.